I’d lose control

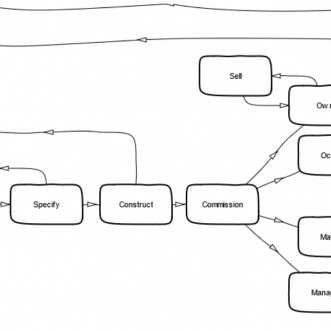

The only way to scale a business that is built around you is to embed the ‘you’ into the way the business works, so that everything about it reminds your prospects and clients of you, even when you are not in the room.

That means enabling and empowering other people to do what you do, as well as or better than you do it. That isn’t losing control, it’s just putting the control in a different place – into the fabric of the business, instead of one or more people’s heads.

Perhaps what’s really behind the worry of ‘losing control’ is the fear of becoming less important to the business. After all, if it can get on perfectly well without you, where does that leave you, the founder, the originator of the vision? The irony is of course, that the more you dig your actual self into the business, the less able it will be to survive without you. All too often, an amazing little business fizzles out with the life of its founder. To my mind, it’s almost criminal to let that happen.

Done well, composing your Customer Experience Score puts you right where you belong – embedded into the heart and soul of the business, without actually having to be present day to day. It’s not just your prospects and clients that will be reminded of you every time they interact with your business, your people will be reminded too. Even those who haven’t joined yet.

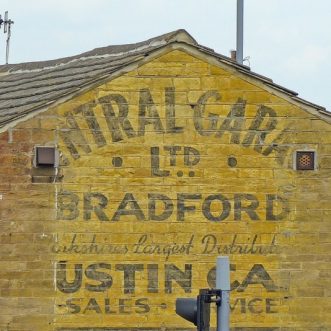

Dale Carnegie has been dead a long while, but the business he founded carries on as world-wide empire, with his vision and philosophy firmly ensconced at its heart.

Isn’t that something worth giving up hands-on control for?